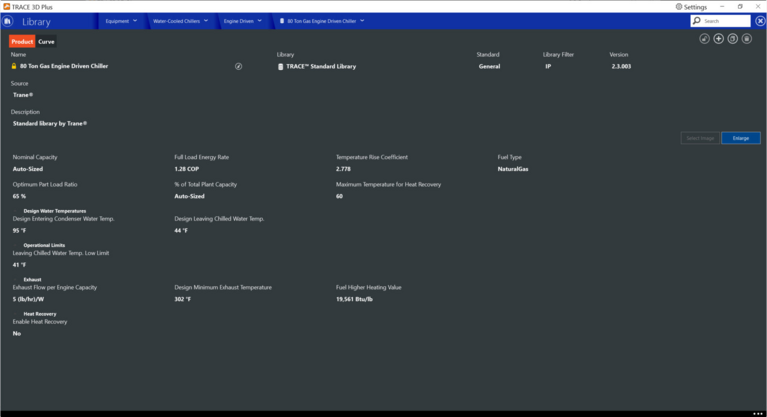

Engine Driven Chiller

The Engine Driven Chiller uses a fuel fired engine to drive the compressor. The fuel can be natural gas, propane gas, diesel or gasoline.

Nominal Cooling Capacity

|

Default: Autosize

|

|

Typical Range: 50 to 500 tons

|

|

Min Max: 0 < X< 999,999

|

|

Units: tons, W, kW, Btuh, Mbh

|

This field specifies the nominal cooling capacity of the chiller.

Full Load Energy Rate

|

Default: 1.28 COP

|

|

Typical Range: 1 to 1.5 COP

|

|

Min Max: 0 to 999,999

|

|

Units: kW/ton, therms/ton-hr, Mbh/ton, kW/Mbh, kW/kW, COP, EER

|

This numeric input field is the chiller’s coefficient of performance.

Temperature Rise Coefficient

|

Default: 2.778

|

|

Typical Range: 2.778

|

|

Min Max: 0 to 999,999

|

|

Units: N/A

|

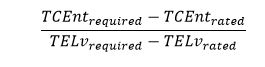

This field contains the electric chiller’s temperature rise coefficient which is defined as the ratio of the required change in condenser water temperature to a given change in chilled water temperature, which maintains the capacity at the nominal value. This is calculated as the following ratio:

where:

TCEntrequired = required entering condenser air or water temperature to maintain rated capacity

TCEntrated = rated entering condenser air or water temperature at rated capacity

TELvrequired = required leaving evaporator water outlet temperature to maintain rated capacity

TELvrated = rated leaving evaporator water outlet temperature at rated capacity

Fuel Type

|

Default: Natural Gas

|

|

Typical Range: N/A

|

|

Min Max: N/A

|

|

Units: N/A

|

This field determines the type of fuel that the chiller uses. Fuel types are: NaturalGas, PropaneGas, Diesel, Gasoline, FuelOil#1, FuelOil#2, OtherFuel1 or OtherFuel2.

Optimum Part Load Ratio

|

Default: 100%

|

|

Typical Range: 10 to 100%

|

|

Min Max: 0 to 100%

|

|

Units: %

|

This numeric field contains the chiller’s optimum part-load ratio. This is the part-load ratio at which the chiller performs at its maximum COP.

Sizing Factor

|

Default: 100%

|

|

Typical Range: 10 to 100%

|

|

Min Max: 0 to 100%

|

|

Units: %

|

The sizing factor is used when the capacity is selected as auto sized. The autosizing calculations are performed as usual and the results are multiplied by the sizing factor.

Max Temp for Heat Recovery

|

Default: 60°F/15.56°C

|

|

Typical Range: 50 to 60°F / 10 to 15.56°C

|

|

Min Max: 50 to 60°F / 10 to 15.56°C

|

|

Units: °F / °C

|

The max temp for heat recovery is the maximum condensing temperature that can be used.

Design Water Temperatures

Design Entering Condenser Water Temperature

|

Default: 95°F/35°C

|

|

Typical Range: 85 to 95°F / 29.4 to 35°C

|

|

Min Max: 75 to 120°F / 23.8 to 35°C

|

|

Units: °F / °C

|

This field contains the combustion turbine chiller’s condenser inlet design temperature.

Design Leaving Chilled Water Temperature

|

Default: 44°F/6.67°C

|

|

Typical Range: 43 to 45°F/ 6.11 to 7.22°C

|

|

Min Max: -130 to 158°F / -90 to 70°C

|

|

Units: °F / °C

|

This field contains the combustion turbine chiller’s evaporator outlet design temperature.

Operational Limits

Leaving Chilled Water Temperature Low Limit

|

Default: 41°F/5°C

|

|

Typical Range: 34 to 41°F/ 1.11 to 5°C

|

|

Min Max: -130 to 158°F / -90 to 70°C

|

|

Units: °F / °C

|

This numeric field contains the lower limit for the evaporator outlet temperature. This temperature acts as a cut off for heat transfer in the evaporator, so that the fluid doesn’t get too cold.

Exhaust

Exhaust Flow per Engine Capacity

|

Default: 0.00063 (kg/s)/W

|

|

Typical Range: Depends on chiller performance

|

|

Min Max: 0 to 99,999,999 kW

|

|

Units: (lb/hr)/W, (kg/s)/W

|

This field contains the maximum exhaust gas mass flow rate per kilowatt of cooling provided by the engine driven chiller.

Design Minimum Exhaust Temperature

|

Default: 32°F

|

|

Typical Range: Depends on chiller performance

|

|

Min Max: 212 to 420°F/100 to 215°C

|

|

Units: °F/°C

|

This field contains the design steam saturation temperature that would be used to determine the energy recovered from a water jacket heat exchanger on the engine.

Fuel Higher Heating Value

|

Default: 43,500 kJ/kg for Natural Gas

|

|

Typical Range: Depends on fuel type

|

|

Min Max: 20267 to 22453 Btu/lb / 47,130 to 52,210 kJ/kg

|

|

Units: Btu/lb, kJ/kg, J/kg

|

Also known as the gross energy of a fuel or gross calorific value. This field contains the higher heating value of the fuel used.

Heat Recovery

Enable Heat Recovery

|

Default: N/A

|

|

Typical Range: N/A

|

|

Min Max: N/A

|

|

Units: Yes/No

|

This field is prompting the user if heat recovery is enabled on this chiller. Heat recovery can be achieved with either a single condenser bundle or an auxiliary condenser.

Heat Recovery Maximum Temperature

|

Default: 140°F

|

|

Typical Range: 100 to 140°F / 37.78 to 60 °C

|

|

Min Max: 100 to 140°F / 37.78 to 60 °C

|

|

Units: °F

|

This field is represents the maximum service-water temperature that can be generated from heat recovery.

Nominal Heat Recovery Capacity

|

Default: 100%

|

|

Typical Range: 50 to 100%

|

|

Min Max: 0 to 100%

|

|

Units: % of cooling capacity

|

This field is represents the amount of thermal energy, as a percentage of the cooling capacity, which can be extracted for service-water heating / pre-heating.

Heat Recovery Pump Type

|

Default: constant speed pump

|

|

Typical Range: N/A

|

|

Min Max: N/A

|

|

Units: N/A

|

This field is represents what pump type is used to circulate hot water to service-water destination. User can choose either constant speed or variable speed.

Heat Recovery Pump

|

Default: 90.1 CV chilled water pump

|

|

Typical Range: N/A

|

|

Min Max: N/A

|

|

Units: N/A

|

This field is represents the actual pump and its’ associated properties that will be used for heat recovery.

Curve tab

The description of the performance curves for the Engine Driven Air cooled chillers is listed below.

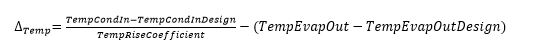

Capacity Ratio Curve

This quadratic curve determines the ratio of available capacity to nominal capacity.

The equation for the Capacity Curve is:

Where:

y = Chiller’s available capacity to nominal capacity ratio (%)

C1 to C3 = coefficients

TempCondIn = Temperature entering the condenser (water or air temperature depending on condenser type)

TempCondInDesign = Temp Design Condenser Inlet from User input above

TempEvapOut = Temperature leaving the evaporator

TempEvapOutDesign = Temp Design Evaporator Outlet from User input above

TempRiseCoefficient = User Input from above

The curve has the following fields:

X Axis: ΔT (°F)

Y Axis: Full Capacity (%)

Curve Type: The curve is quadratic

ΔT Min / Max: Minimum and Maximum Delta T

Capacity –Power Curve (Power ratio curve)

This quadratic curve shows the percentage of full power capacity as a function of the chiller’s capacity. The equation for the Capacity-Power Curve is:

Where:

C1 to C3 = coefficients

The curve has the following fields:

X Axis: Full capacity (%)

Y Axis: Full Power (%)

Curve Type: The curve is quadratic

Capacity Min / Max: Minimum and Maximum percentage of the capacity

Power Curve (Full Load Ratio )

This quadratic curve determines the fraction of full load power. The equation for the Capacity-Power Curve is:

Where:

C1 to C3 = coefficients

The curve has the following fields:

X Axis: Full capacity (%)

Y Axis: Full Power (%)

Curve Type: The curve is quadratic

Capacity Min / Max: Minimum and Maximum percentage of the capacity

Fuel used Curve (Fuel Input curve )

This quadratic curve determines the Ratio of Cooling Load to Fuel Energy. The equation for the Fuel used Curve is:

Where:

C1 to C3 = Coefficients

PLR = Part Load Ratio

The curve has the following fields:

X Axis: Full load (%)

Y Axis: Full Power (%)

Curve Type: The curve is quadratic

Capacity Min / Max: Minimum and Maximum percentage of the load

Jacket Heat Recovery Curve

This quadratic curve determines the ratio of heat recovery to fuel energy. The equation for the Jacket Heat Recovery Curve is:

Where:

y = Heat Recovery Ratio

C1 to C3 = coefficients

RL = Ratio of Load to Engine Capacity

The curve has the following fields:

X Axis: Ratio of Load to Diesel Energy Consumption

Y Axis: Heat Recovery Ratio (%)

Curve Type: The curve is quadratic

Full Load Min / Max: Minimum and Maximum percentage of the load to capacity

Lube Heat Recovery Curve

This quadratic curve determines the ratio of recovery lube heat to fuel energy. The equation for the Jacket Heat Recovery Curve is:

Where:

y = Heat Recovery Ratio

C1 to C3 = coefficients

RL = Ratio of Load to Engine Capacity

The curve has the following fields:

X Axis: Ratio of Load to Diesel Energy Capacity

Y Axis: Heat Recovery Ratio (%)

Curve Type: The curve is quadratic

Full Load Min / Max: Minimum and Maximum percentage of the load to capacity

Total Exhaust Energy Curve

This quadratic curve determines the ratio of total exhaust energy to fuel energy. The equation for the Total Exhaust Energy is:

Where:

y = Heat Recovery Ratio

C1 to C3 = coefficients

RL = Ratio of Load to Engine Capacity

The curve has the following fields:

X Axis: Ratio of Load to Diesel Energy Capacity

Y Axis: Exhaust Temperature (%)

Curve Type: The curve is quadratic

Exhaust Temperature Curve

This quadratic curve determines the Ratio of Fuel Input to the Temperature Difference between the current and design ambient temperatures. The equation for the Exhaust Temperature is:

Where:

y = Heat Recovery Ratio

C1 to C3 = coefficients

RL = Ratio of Load to Engine Capacity

The curve has the following fields:

X Axis: ΔT (°F)

Y Axis: Exhaust Temperature (%)

Curve Type: The curve is quadratic

UA Capacity Curve

The U-Factor times Area (UA) is an equation that determines the overall heat transfer coefficient for the exhaust gasses with the stack:

Where:

y = UA

C1 to C2 = coefficients

The curve has the following fields:

X Axis: Load to Capacity (%)

Y Axis: Heat Recovery (%)

Curve Type: The curve is quadratic