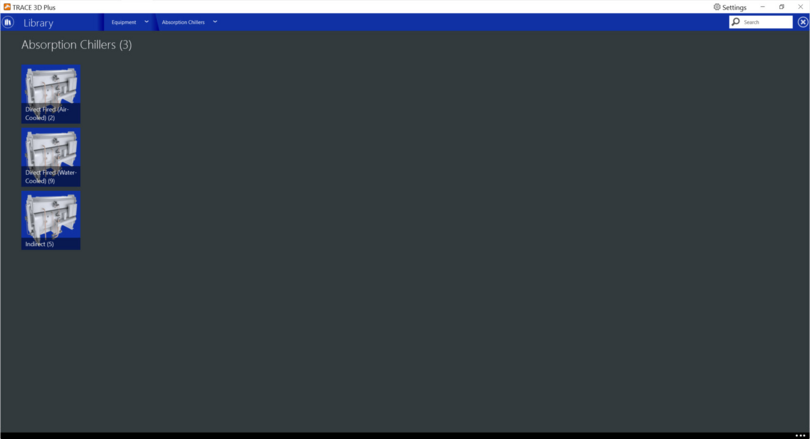

Absorption Chillers

Absorption chillers use heat to drive the refrigeration cycle, they produce chilled water while consuming just a small amount of electricity to run the pumps on the unit. Absorption chillers generally use steam or hot water to drive the lithium bromide refrigeration cycle but can also use other heat sources. There are three types of Absorption chillers in this library.