Chilled Beams

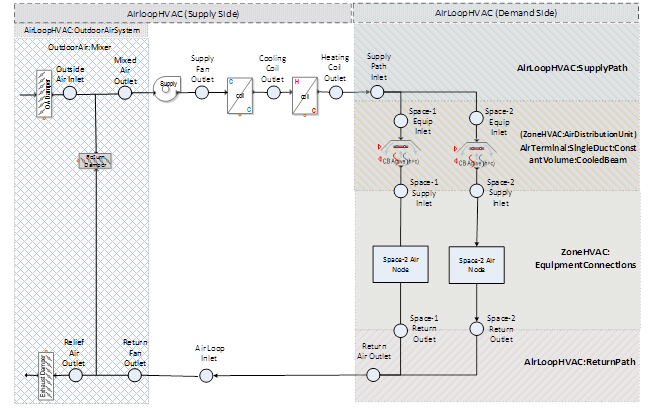

Active Chilled Beams

General Description

This system has a central air handler with integral heating and cooling coils that can supply either heated or cooled supply air to one or more rooms also served by active chilled beams. In cooling mode the primary air handler typically delivers supply air at about 65F to the active chilled beam units located in the ceiling where room air from below is induced through the chilled beams’ convective cooling coils. Warm air rising in the space pools at the lower level of the ceiling which causes the air to contact the chilled water coil. The cooled air then falls naturally into the space due to its negative buoyancy. The chilled beam units are only activated if the primary supply air is inadequate to meet the space cooling load. In heating and deadband mode, the chilled beam units and main cooling coil are deactivated. The main heating coil is only sized to preheat the mixed air up to a neutral temperature, usually equal to the design room heating dry bulb or it can be used to preheat up to the economizer control point.

Controlling Coil Setpoints

There are a number of ways to control the primary AHU’s cooling and heating coils. Usually, for this system, the main purpose of the primary AHU’s heating coil is only to preheat (if necessary) the return/OA mixture, (ROADB), to each time step’s economizer control point where the supply air dry bulb (SADB) is the temperature to satisfy either the control room’s cooling thermostat or the worst-case room’s cooling thermostat. (Remember: this system has a single AHU serving multiple rooms and so must decide which room or rooms to base its response on.) The purpose of the primary AHU’s cooling coil is to satisfy the ventilation cooling load plus the room latent load plus a portion (but not all) of the room(s) space cooling load.

To base the AHU’s response on a single room’s control thermostat, use “Supply air reset per single zone load” temperature control on the controls tab of the system properties and set the range of SADB from Design SADBC to Design room dry bulb in heating and define which room contains the control thermostat in the control zone field.

Alternatively, to base the AHU’s response on the worst-case cooling room, use the “Supply air reset per OA and worst case zone” temperature control with the same SADB range. Since the primary purpose of the main heating coil is to preheat, use a temperature controller to control the outlet of the primary AHU’s heating coil. So if the control thermostat is calling for a certain SADB, and the return/OA mixture is below SADB (minus fan heat), the main heating coil (located upstream of the main cooling coil) will preheat ROADB to SADB (minus fan heat).

For a draw-thru configuration, when the return/OA mixture is above SADB (minus fan heat), the cooling coil is activated to produce Cldbc=SADB-FanTD where Cldbc is the off cooling coil temperature and FanTD is the fan heat gain

For a blow-thru configuration, when the return/OA mixture (plus fan heat) is above SADB, the cooling coil is activated to produce Cldbc=SADB. Alternatively, a “Supply air reset per single zone load” temperature control could be used at the supply air outlet to operate the primary AHU’s coils like a VTCV (variable temperature constant volume) system. Warning: fighting between the cooling and heating coils will occur between the primary AHU’s cooling and heating coils if proper temperature controls are not chosen or set up properly.

Another, perhaps more common method, is to use the “Supply air reset per OA” temperature control to change the primary AHU’s supply air setpoint depending on the outdoor temperature.

Sizing Considerations

The chilled beams handle only a portion of the room sensible load and none of the room latent since we don’t want condensation to occur on the chilled beams. Choosing the primary AHU’s cooling coil’s design SADBClg is tricky because the SADB in combination with a minimum airflow setting will determine the required capacity of the downstream chilled beams, i.e., the chilled beam capacity for a given room will equal the room space load minus whatever the central system supplies, i.e., DsnChBeamSensCapclg = DsnRmSpaceSensibleLoadclg - CpAir*RhoAir*DesAirVolFlow* (DsRmdbclg - DsnSADBClg).

If the primary job of the primary AHU’s heating coil is to preheat the supply air, then set Design SADBHtg equal to the design room heating dry bulb, DsRmdbhtg. If “Supply air reset per single zone load” temperature controller and was chosen then setting DsnSADBHtg = DsRmdbhtg will restrict the primary AHU’s main heating coil’s heating capacity so it can do little more than preheat the supply air; however, setting DsnSADBHtg to a value above DsRmdbhtg will give the primary AHU’s heating coil more capacity.

However, the baseboards – generally needed for the two-pipe chilled beam configuration, in the rooms will not know about how the primary AHU’s heating coil was sized and so the baseboard capacity will default to the design zone space sensible heating load. For a four-pipe beam configuration, a baseboard is generally not needed and so the heating capacity of the beam can be autosized correctly. If the primary AHU operates as a VTCV unit, the primary airflow can provide part of the space heating load directly but more often than not, the primary SADB is controlled by OA reset and/or the primary AHU may need to operate in direct dehumidification mode to prevent condensation on the chilled beams, and so the beam heating coil must also provide reheat capability.

To support worst case, the beam heating coil should autosize as FinalZoneSizing.DesHeatLoad + (reheat CoolBeam.MaxAirVolFlow from FinalSysSizing.CoolSupTemp to FinalZoneSizing.ZoneTempAtHeatPeak) and assume no space heating credit from the primary AHU subject to special sizing options on the chilled beam object.

Application Considerations

1. It is unwise to set the primary AHU’s sizing method to Ventilation Requirement for active chilled beams. The performance of the active chilled beams is directly tied to the amount of the primary airflow delivered to the chilled beams. Since the chilled beams are autosized according to the remainder of the room sensible load not met by the primary AHU, then the chilled beams may be either over- or under-aired and so be unable to operate properly. It is better to use a minimum flow rate input, e.g., 4 l/s/m2

2. To achieve proper room temperature control, the best practice is to create each primary AHU so its attached rooms have a similar façade (i.e. all walls facing same direction with similar proportion of glass). During annual operation, this allows the primary AHU to respond to a similar thermostat signal. It would be unwise, for example, for the primary AHU delivering air to a south-facing room in cooling mode while a north-facing room in the same zone requires heating. While the chilled beams or baseboard convectors in each room can respond as necessary to their remaining space sensible load, this is likely to waste energy.

3. During the annual energy simulation, the primary AHU of an active chilled beam system will reset its SADB depending on the choice of temperature control. If a cooling load still exists in some of the rooms, the chilled beams in those rooms will then operate to finish off any space sensible load not met by the primary AHU. However, the chilled beam controls will throttle back the chilled beam flow rate if they detect that condensation is about to begin on the chilled beams. Typically, this happens when the primary SADB is too high at a time when the room relative humidity is high and because the user has changed the humidity control from "Supply air reset per maximum” to “Supply air reset” or because the primary AHU’s average thermostat signal is not representative of the worst-case cooling room. If the chilled beams were forced to throttle back their capacity to avoid condensation, this can lead to unmet loads and overly warm room temps.

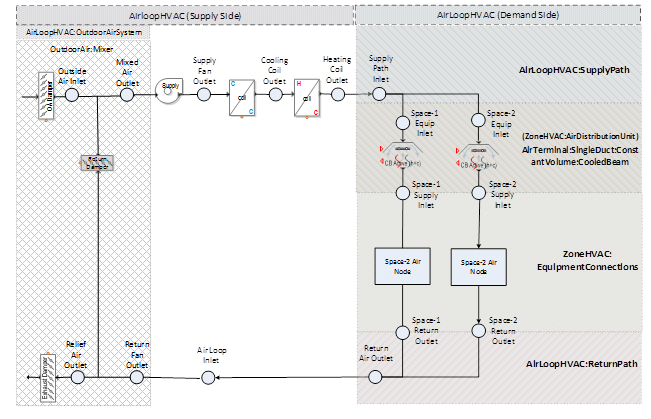

Passive Chilled Beams

General Description

Passive chilled beams are essentially bare chilled water coils which can either be recessed or suspended from the ceiling that rely on natural convection to transport warm air vertically to the beam location. The room air is then naturally drawn through the perforated ceiling over the top of the passive chilled beams, and the cooled air drops from the underside of the beam and cools the space. The passive chilled beams are supplemented by an all air system which takes care of ventilation as well as the latent load component.

Controlling Coil Setpoints

There are a number of ways to control the primary AHU’s cooling and heating coils. Usually, for this system, the main purpose of the primary AHU’s heating coil is only to preheat (if necessary) the return/OA mixture, (ROADB), to each time step’s economizer control point where the supply air dry bulb (SADB) is the temperature to satisfy either the control room’s cooling thermostat or the worst-case room’s cooling thermostat. (Remember: this system has a single AHU serving multiple rooms and so must decide which room or rooms to base its response on.) The purpose of the primary AHU’s cooling coil is to satisfy the ventilation cooling load plus the room latent load plus a portion (but not all) of the room(s) space cooling load.

To base the AHU’s response on a single room’s control thermostat, use “Supply air reset per single zone load” temperature control on the controls tab of the system properties and set the range of SADB from Design SADBC to Design room dry bulb in heating and define which room contains the control thermostat in the control zone field.

Alternatively, to base the AHU’s response on the worst-case cooling room, use the “Supply air reset per OA and worst case zone” temperature control with the same SADB range. Since the primary purpose of the main heating coil is to preheat, use a temperature controller to control the outlet of the primary AHU’s heating coil. So if the control thermostat is calling for a certain SADB, and the return/OA mixture is below SADB (minus fan heat), the main heating coil (located upstream of the main cooling coil) will preheat ROADB to SADB (minus fan heat).

For a draw-thru configuration, when the return/OA mixture is above SADB (minus fan heat), the cooling coil is activated to produce Cldbc=SADB-FanTD where Cldbc is the off cooling coil temperature and FanTD is the fan heat gain.

For a blow-thru configuration, when the return/OA mixture (plus fan heat) is above SADB, the cooling coil is activated to produce Cldbc=SADB. Alternatively, a “Supply air reset per single zone load” temperature control could be used at the supply air outlet to operate the primary AHU’s coils like a VTCV (variable temperature constant volume) system. Warning: fighting between the cooling and heating coils will occur between the primary AHU’s cooling and heating coils if proper temperature controls are not chosen or set up properly.

Another, perhaps more common method, is to use the “Supply air reset per OA” temperature control to change the primary AHU’s supply air setpoint depending on the outdoor temperature.

Sizing Considerations

The chilled beams handle only a portion of the room sensible load and none of the room latent since we don’t want condensation to occur on the chilled beams. Choosing the primary AHU’s cooling coil’s design SADBClg is tricky because the SADB in combination with a minimum airflow setting will determine the required capacity of the downstream chilled beams, i.e., the chilled beam capacity for a given room will equal the room space load minus whatever the central system supplies, i.e., DsnChBeamSensCapclg = DsnRmSpaceSensibleLoadclg - CpAir*RhoAir*DesAirVolFlow* (DsRmdbclg - DsnSADBClg).

If the primary job of the primary AHU’s heating coil is to preheat the supply air, then set Design SADBHtg equal to the design room heating dry bulb, DsRmdbhtg. If “Supply air reset per single zone load” temperature controller and was chosen then setting DsnSADBHtg = DsRmdbhtg will restrict the primary AHU’s main heating coil’s heating capacity so it can do little more than preheat the supply air; however, setting DsnSADBHtg to a value above DsRmdbhtg will give the primary AHU’s heating coil more capacity.

However, the baseboards – generally needed for the two-pipe chilled beam configuration, in the rooms will not know about how the primary AHU’s heating coil was sized and so the baseboard capacity will default to the design zone space sensible heating load. For a four-pipe beam configuration, a baseboard is generally not needed and so the heating capacity of the beam can be autosized correctly. If the primary AHU operates as a VTCV unit, the primary airflow can provide part of the space heating load directly but more often than not, the primary SADB is controlled by OA reset and/or the primary AHU may need to operate in direct dehumidification mode to prevent condensation on the chilled beams, and so the beam heating coil must also provide reheat capability.

To support worst case, the beam heating coil should autosize as FinalZoneSizing.DesHeatLoad + (reheat CoolBeam.MaxAirVolFlow from FinalSysSizing.CoolSupTemp to FinalZoneSizing.ZoneTempAtHeatPeak) and assume no space heating credit from the primary AHU subject to special sizing options on the chilled beam object.

Application Considerations

1. It is unwise to set the primary AHU’s sizing method to Ventilation Requirement for active chilled beams. The performance of the active chilled beams is directly tied to the amount of the primary airflow delivered to the chilled beams. Since the chilled beams are autosized according to the remainder of the room sensible load not met by the primary AHU, then the chilled beams may be either over- or under-aired and so be unable to operate properly. It is better to use a minimum flow rate input, e.g., 4 l/s/m2

2. To achieve proper room temperature control, the best practice is to create each primary AHU so its attached rooms have a similar façade (i.e. all walls facing same direction with similar proportion of glass). During annual operation, this allows the primary AHU to respond to a similar thermostat signal. It would be unwise, for example, for the primary AHU delivering air to a south-facing room in cooling mode while a north-facing room in the same zone requires heating. While the chilled beams or baseboard convectors in each room can respond as necessary to their remaining space sensible load, this is likely to waste energy.

3. During the annual energy simulation, the primary AHU of an active chilled beam system will reset its SADB depending on the choice of temperature control. If a cooling load still exists in some of the rooms, the chilled beams in those rooms will then operate to finish off any space sensible load not met by the primary AHU. However, the chilled beam controls will throttle back the chilled beam flow rate if they detect that condensation is about to begin on the chilled beams. Typically, this happens when the primary SADB is too high at a time when the room relative humidity is high and because the user has changed the humidity control from "Supply air reset per maximum” to “Supply air reset” or because the primary AHU’s average thermostat signal is not representative of the worst-case cooling room. If the chilled beams were forced to throttle back their capacity to avoid condensation, this can lead to unmet loads and overly warm room temps.