Systems Library

The System Library is where you can create a custom system to be used in an alternative. The System can be created new or can be copied from an existing system and edited. The components that are available to be applied to a system are in the component selection section.

*Incomplete systems can be saved, but cannot be selected in an actual file.

System Categories Screen

The System Categories Screen shows the list of System Categories and the number of Systems in the library for each system. The number includes both the standard libraries and custom libraries. You can also navigate to a different library using the System dropdown. Additionally, you can search for a specific library by name in the Search Library Field.

After a system category has been selected, the list of all the systems in that category will appear. This list contains both the standard systems, and user created custom system libraries categorized into folders. Any system can be selected to view however only the custom systems can be edited. Standard systems can be copied and the copy can be edited.

The user can also create a new custom system library member by clicking the Add Item button or create a new folder by clicking the Add Group button.

Add Group

This button is used to create a new folder within the System Category. For example, if a number of different custom system libraries are used for the same project, they can be organized together in one group folder in order to find them more easily.

Add Item

This button is used to create a new system library in the current system category.

Library Dropdown

The Library dropdown allows the user to navigate to a different library such as the equipment library or materials library.

Systems Category Dropdown

The systems category dropdown allows the user to navigate to a different system category for example to the 90.1 Systems category or the Variable Air Volume (VAV) category.

Search Library

The search window allows the user to search for a specific library member by name.

Patterns Screen

The first step in creating a new system library is to choose an air path pattern. The available air paths for the selected system category will be listed. System components will be added to the air path after the pattern is selected.

Below is a table that shows which patterns are available for each system category:

|

System

|

VAV

|

CV

|

Double Duct

|

Chilled Beam and Induction

|

Cooling Only

|

Heating Only

|

UFAD

|

DV

|

DOA

|

90.1

|

|

Single Duct

|

x

|

x

|

|

x

|

x

|

x

|

|

|

|

x

|

|

Single Duct w/RA Bypass

|

x

|

x

|

|

x

|

x

|

x

|

|

|

|

|

|

UFAD

|

|

|

|

x

|

|

|

x

|

|

|

|

|

UFAD w/ RA Bypass

|

|

|

|

x

|

|

|

x

|

|

|

|

|

DV

|

|

|

|

x

|

|

|

|

x

|

|

|

|

DV w/RA Bypass

|

|

|

|

x

|

|

|

|

x

|

|

|

|

Dual Duct

|

|

|

x

|

|

|

|

|

|

|

|

|

90.1 Zone Level System

|

|

|

|

|

|

|

|

|

|

x

|

|

Variable Volume Zone Level System

|

x

|

|

|

|

|

|

|

|

|

|

|

Constant Volume Zone Level System

|

|

x

|

|

|

|

|

|

|

|

|

|

Variable Refrigerant Flow

|

x

|

|

|

|

|

|

|

|

|

|

|

Cooling Only Zone Level Systems

|

|

|

|

|

x

|

|

|

|

|

|

|

Heating Only

|

|

|

|

|

|

x

|

|

|

|

|

|

DOA to Single Systems

|

|

|

|

|

|

|

x

|

|

x

|

|

|

DOA to Multiple Systems

|

|

|

|

|

|

|

|

|

x

|

|

|

DOA to Zone

|

|

|

|

|

|

|

|

|

x

|

|

|

Mechanical Ventilation Only System

|

|

|

|

|

|

|

|

|

x

|

|

|

| |||

|

| |||

|

| |||

|

|

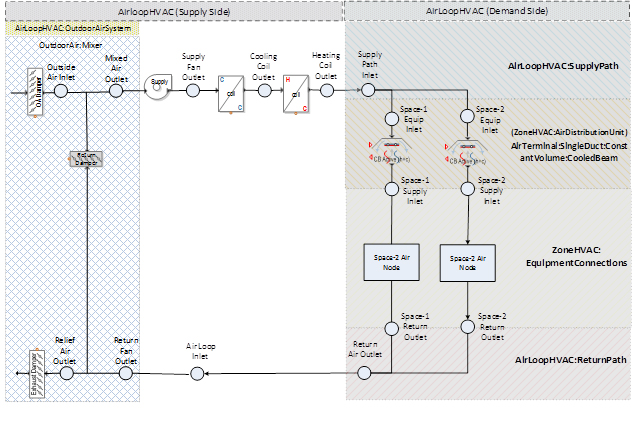

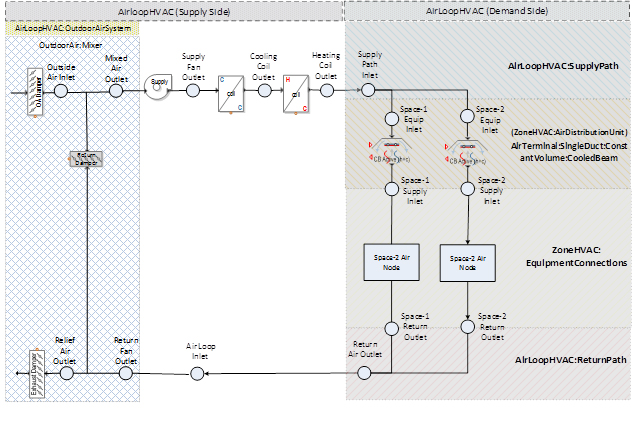

Single Duct

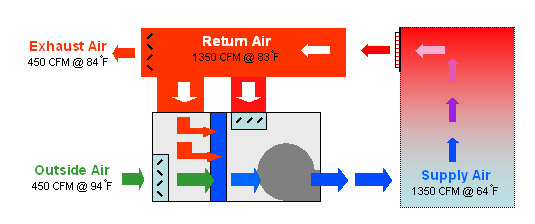

The single duct pattern is available for the VAV, CV, Chilled Beam and Induction, Cooling Only, Heating Only, and 90.1 system categories. The single duct pattern allows for a single stream of air to be delivered to the zones assigned to the system.

Coils and fans will be at the system level and one set of coils and fans will serve all zones assigned to the system.

90.1 Single Duct with RA Bypass

The single duct with RA bypass pattern is available for the VAV, CV, Chilled Beam and Induction, Cooling Only,and Heating Only system categories.

The single duct with RA bypass pattern is typically used to bypass return air around the main cooling coil. This allows the cooling coil to over cool the air for dehumidification and reheat it using the bypassed return air.

Coils and fans will be at the system level and one set of coils and fans will serve all zones assigned to the system.

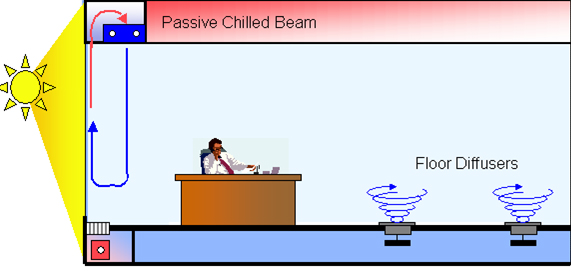

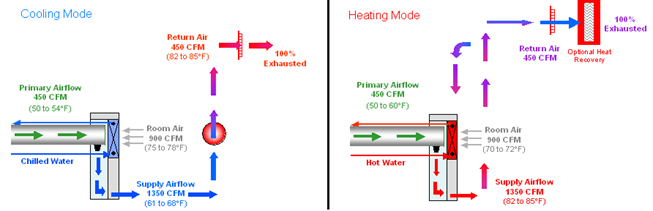

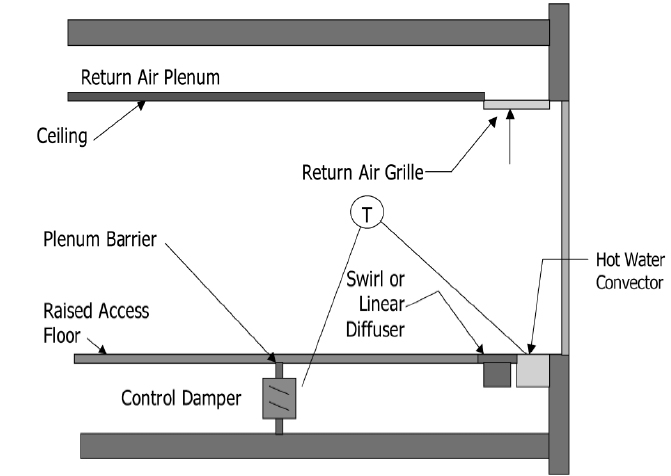

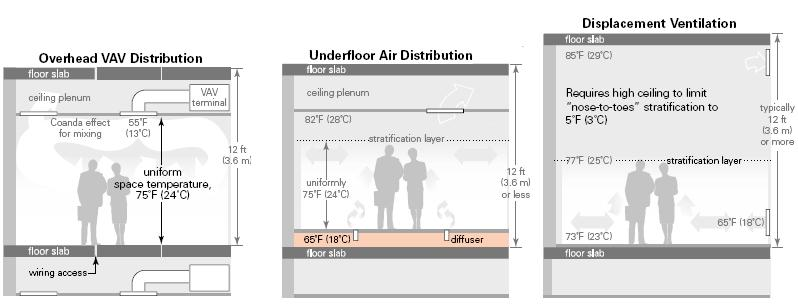

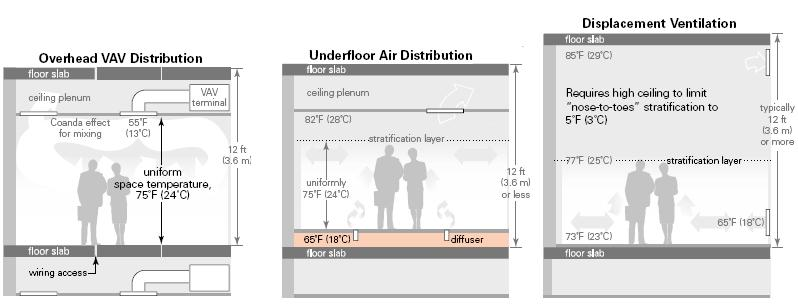

UFAD

The UFAD pattern is available only for the UFAD and Chilled Beam and Induction system types. This pattern configuration allows air to be supplied from an under-floor plenum instead of from the ceiling. Coils and supply fans will be placed in the underfloor plenum.

Coils and fans will be at the system level and one set of coils and fans will serve all zones assigned to the system.

UFAD with RA Bypass

The UFAD with RA Bypass pattern is available only for the UFAD and Chilled Beam and Induction system types. This pattern configuration allows air to be supplied from an under-floor plenum instead of from the ceiling. Coils and supply fans will be placed in the underfloor plenum.

Return air is bypassed around the main cooling coil. This allows the cooling coil to overcool the air for dehumidification and reheat it using the return air.

Coils and fans will be at the system level and one set of coils and fans will serve all zones assigned to the system.

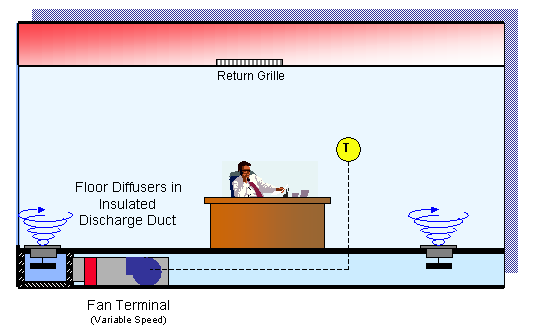

DV

The DV pattern is available only for the DV and Chilled Beam and Induction system types. This pattern configuration allows air to be supplied through diffusers near the floor of the zone instead of the ceiling. Coils and supply fans will be placed in the underfloor plenum.

Coils and fans will be at the system level and one set of coils and fans will serve all zones assigned to the system.

DV with RA Bypass

The DV with RA Bypass pattern is available only for the DV and Chilled Beam and Induction system types. This pattern configuration allows air to be supplied through diffusers near the floor of the zone instead of the ceiling. Coils and supply fans will be placed in the underfloor plenum.

Return air is bypassed around the main cooling coil. This allows the cooling coil to overcool the air for dehumidification and reheat it using the return air.

Coils and fans will be at the system level and one set of coils and fans will serve all zones assigned to the system.

Dual Duct

The Dual Duct pattern is available only for the Dual Duct system category. This pattern is similar to the Single Duct pattern but with an additional parallel air path. The main supply air path splits into a cold deck and hot deck. The cold deck flows through the cooling coil and the hot deck flows through the heating coil. The two paths remix in the zone to achieve the desired supply air temperature.

Uniformly mixed return air is drawn from a common return air plenum.

Coils and fans will be at the system level and one set of coils and fans will serve all zones assigned to the system.

90.1 Zone Level System

The 90.1 Zone Level System is only available for the 90.1 system category. The pattern is used for creating 90.1 systems with zone/room level equipment.

When creating a zone level system, only Zone Level Equipment will be available. The zone level equipment library will define the coils, fans, and controls for the system. There will be no air path displayed on the system diagram and there will be no system level components, terminal devices or controls available to add to the system. The user will only need to select the zone level equipment and place it in the demand box to create the system library.

Variable Volume Zone Level System

The Variable Volume Zone Level System is only available for the VAV system category. This pattern is used to create systems with zone level VAV equipment. The zone level equipment available for this pattern is:

When creating a zone level system, only Zone Level Equipment will be available. The zone level equipment library will define the coils, fans, and controls for the system. There will be no air path displayed on the system diagram and there will be no system level components, terminal devices or controls available to add to the system. The user will only need to select the zone level equipment and place it in the demand box to create the system library.

Constant Volume Zone Level System

The Constant Volume Zone Level System is only available for the CV system category. This pattern is used to create systems with zone level CV equipment. The zone level equipment available for this pattern is:

When creating a zone level system, only Zone Level Equipment will be available. The zone level equipment library will define the coils, fans, and controls for the system. There will be no air path displayed on the system diagram and there will be no system level components, terminal devices or controls available to add to the system. The user will only need to select the zone level equipment and place it in the demand box to create the system library.

Variable Refrigerant Flow

The Variable Refrigerant Flow pattern is only available for the VAV system category. This pattern is used to create a variable refrigerant flow system. The zone level equipment available for this pattern is:

When creating a zone level system, only Zone Level Equipment will be available. The zone level equipment library will define the coils, fans, and controls for the system. There will be no air path displayed on the system diagram and there will be no system level components, terminal devices or controls available to add to the system. The user will only need to select the zone level equipment and place it in the demand box to create the system library.

Cooling Only Zone Level System

The Cooling Only Zone Level System pattern is only available for the Cooling Only system category. This pattern is used to create cooling only systems with zone level equipment. The zone level equipment available or this system is:

|

Window Air Conditioner

|

Evaporative Cooler Unit

|

Unit Ventilator (Cooling Only)

|

Variable Refrigerant Flow

|

When creating a zone level system, only Zone Level Equipment will be available. The zone level equipment library will define the coils, fans, and controls for the system. There will be no air path displayed on the system diagram and there will be no system level components, terminal devices or controls available to add to the system. The user will only need to select the zone level equipment and place it in the demand box to create the system library.

Heating Only

The Heating Only pattern is only available for the Heating Only system category. This pattern is used to create heating only systems with zone level equipment. The zone level equipment available for this system is:

|

Wall Cover

|

Radiant Heat

|

Unit Heater Heating Only

|

Unit Ventilator Heating Only

|

|

Variable Refrigerant Flow

(Heating Mode)

|

Ceiling Radiant Panel (Heating Only)

|

Infloor Radiant Panel (Heating Only)

|

|

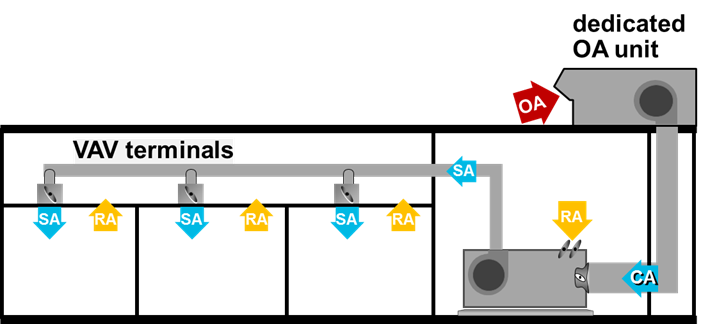

The DOA patterns are used to create Dedicated Outdoor Air systems to condition outside air. The DOA to Single System pattern allows the user to create a DOA that will be assigned to a system that has system level equipment.

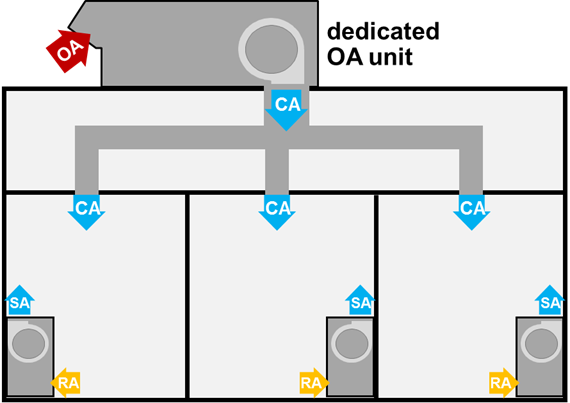

DOA to Multiple Systems

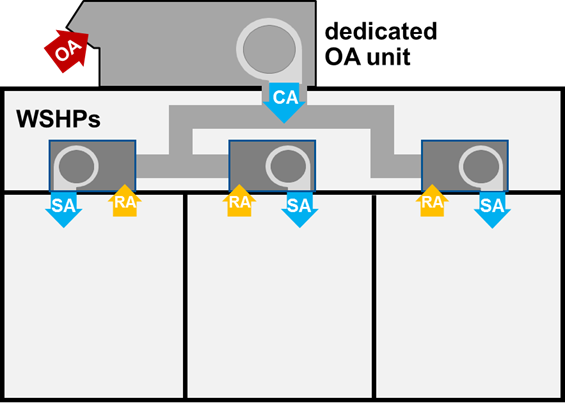

The DOA patterns are used to create Dedicated Outdoor Air systems to condition outside air. The DOA to Multiple Systems is used to create a DOA system that will be assigned to multiple zone level systems. This pattern is only available to be assigned to zone level fan coil and WSHP systems. This is a current limitation of EnergyPlus™.

DOA to Zone

The DOA patters are used to create Dedicated Outdoor Air systems to condition outside air. The DOA to Zone pattern is used to create DOA systems that will be assigned system that have zone level equipment except zone level fan coil and WSHP systems. These systems should use the DOA to Multiple Systems pattern.

Ventilation Only System

The Ventilation Only System is used for 100% OA systems in place of a standard system.

Systems List

There are 10 system categories. Each system category contains standard libraries but custom libraries can also be added to each category.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Variable Air Volume (VAV)

Each system type contains description of the system and its components.

|

|

|

|

|

|

|

|

Changeover-Bypass VAV

This system has a central air handler with integral heating and cooling coils that can supply either heated or cooled supply air to one or more rooms. The volume supplied to each zone is individually regulated by a zone VAV damper. Each VAV damper is linked to a zone thermostat sensor, thus enabling the occupants to choose their own local space temperature. Treated air is supplied to the zone VAV dampers via a network of low velocity ductwork supplied from a built-up air handling unit or a packaged rooftop unit. This central unit delivers a constant volume of air but is sized according to the block (coincident) cooling load. Any air that is not needed to heat or cool the rooms is simply returned back to the air handling unit via a system-level bypass loop. Each room VAV damper communicates with the main AHU as to whether the room requires hot or cold air to satisfy the room setpoint temperature.

Priority Control Mode

The operation of the VAV dampers in conjunction with the primary cooling and heating coils is determined by the Operating Mode in the changeover-bypass VAV equipment library. If Cooling Priority is selected, the system operates to meet the cooling load if any zone served by this system (air loop) requires cooling. If no zones require cooling, then the system operates in heating mode if needed. If Heating Priority is selected, the system operates to meet the heating load if any zone requires heating. If no zones require heating, then the system operates in cooling mode if needed. If Highest Mode Priority is selected, the system operates based on the maximum number of zones requiring either heating or cooling. If the number of zones requiring cooling is greater than the number of zones requiring heating, then the system operates in cooling mode. If the number of zones requiring heating is greater than the number of zones requiring cooling, then the system operates in heating mode. If the number of zones requiring cooling equals the number of zones requiring heating, then the largest combined load (i.e., the sum of the cooling loads for zones requiring cooling compared to the sum of the heating loads for zones that require heating) sets the cooling or heating operating mode for the system during that simulation time step. The operation of the individual room VAV dampers depends on the Air Terminal device chosen.

Deadband Mode

If none of the rooms are in either cooling or heating mode, then both the cooling and heating coils are deactivated, and the fan runs per the field “System Air Flow Rate When No Cooling or Heating is Needed. This is written behind the scenes and is autosized based on the system loads. This field is only used when the unitary system’s supply air fan cycling mode is specified as continuous fan operation. If the system’s supply air fan cycling mode is specified as continuous fan operation and this value is set to zero or the field is left blank, then the model assumes that the system air flow rate when no heating/cooling is needed is equal to the system air flow rate when the coils were last operating (for cooling operation or heating operation).

Real-life Application Considerations

This system is best suited to applications that require either heating or cooling but not both since at any given time the air handling unit must supply either warm or cool air. For isolated rooms that may occasionally require heating when the rest of the system needs cooling, electric or hot water reheat coils or baseboards can be provided to maintain comfort conditions. To satisfy minimum ventilation requirements, a room VAV minimum supply air setting can be defined to guarantee a minimum supply airflow into the room even if there is no demand for heating or cooling.

Changeover-Bypass VAV with Local Heat

Notice that in this configuration, the VAV boxes have no reheat coil, just a damper. The user could easily switch out the baseboard with a floor or ceiling radiant panel in the zone equipment tab of the systems section in the project.

Cooling Mode Operation

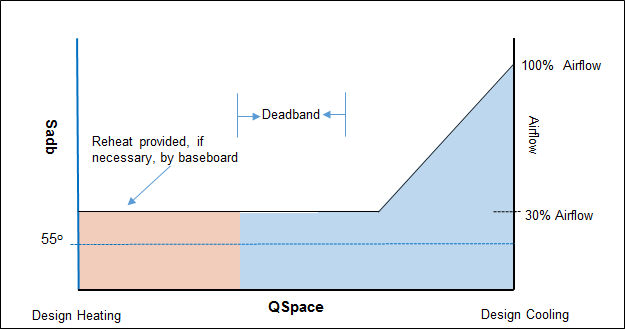

If the AHU is in cooling mode, the VAV damper opens as needed in each room to provide sensible cooling to those room(s); however, with the AHU in cooling mode, the room(s) needing heat or in the deadband will receive cold supply air equal to the VAV minimum setting. See figure below. If this cold minimum supply airflow causes the space temperature to fall below a room’s heating thermostat, that room’s baseboard unit will activate to meet this “reheat” load.

Heating Mode Operation

If the majority of rooms call for heating, the rooms are first served by their VAV box which will increase the heated supply air flow rate as needed to meet higher space heating loads. See figure below. If however, this heated supply air is inadequate to meet an individual room’s heating thermostat setpoint, the baseboard is activated to meet this remaining load. Any rooms that do not require heating will still receive heated supply airflow equal to their VAV minimum airflow setting and could temporarily lose control of their space temperature.

Changeover-Bypass VAV with Reheat

Notice that in the above configuration, the VAV boxes include a reheat coil as the only source of heating, and the damper heating action is set to Dual Maximum.

Cooling Mode Operation

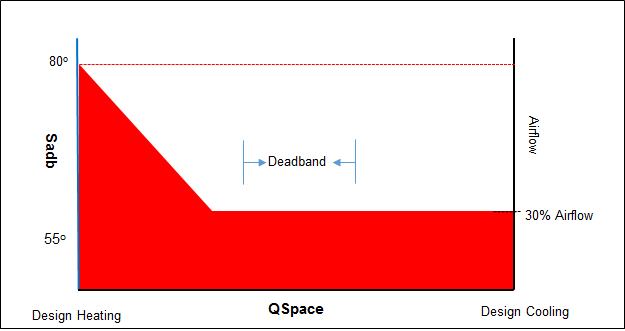

If the AHU is in cooling mode, the VAV damper opens as needed in each zone to provide sensible cooling to those zone(s); however, with the AHU in cooling mode, the zone(s) needing heat or in the deadband will receive cold supply air equal to the VAV minimum setting. See figure below. If this cold minimum supply airflow causes the space temperature to fall below a room’s heating thermostat, that room’s reheat coil will activate to meet this “reheat” load.

Heating Mode Operation

If the majority of rooms call for heating, the rooms are first served by their VAV box which will increase the heated supply air flow rate as needed to meet higher space heating loads. See figure below. If additional heat is required (beyond what the terminal unit can provide with its damper fully open), then the reheat coil is modulated as needed to meet the additional heating load. Any rooms that do not require heating will still receive heated supply airflow equal to their VAV minimum airflow setting and could temporarily lose control of their space temperature.

Fan Powered VAV

Parallel Fan Powered VAV

The design is block air and block cooling capacity. This system is composed of a central, variable volume fan located on the cold deck that supplies cool air to each zone’s fan-powered VAV box. The return side of the fan powered box is said to be on the runaround deck since it draws plenum air from above the room served by the fan-powered box. The cooling supply fan is variable volume and will modulate in proportion to the sum of the cold deck airflows.

System Simulation

For non-mixing situations, the sequence of events is as follows. When the room drift temperature has risen above the room cooling thermostat, the cold deck side of the room mixing box is opened. The resulting room airflow is proportional to the room's design cooling load. When the room drift temperature drops below the room heating thermostat, only the return air side of the room mixing box opens and the unit fan is activated. The heating coil is activated within the fan-powered unit if the runaround air is unable to maintain the space above the heating thermostat setpoint. The unit fan is on for the portion of the hour it takes to bring up or maintain the room at the heating thermostat setpoint. When the room drift temperature lies within the dead band region, both the return air and the cold deck sides of the room mixing box are closed and no supply air is admitted to the space.

Mixing situations can occur in a room mixing box only when a reheat minimum airflow has been specified. A minimum stop defines the minimum amount of cold deck airflow that must be delivered to each space. As long as the room drift temperature stays above the room heating thermostat, no mixing takes place and the mixing box supplies air only from the cold deck. If, however, the room drift temperature falls below the heating thermostat settings, the runaround deck also opens such that the mixture of the warm and cool airflows controls the room temperature to the heating thermostat. Thus, as long as the room drift temperature remains in the dead band region, the room cold deck airflow will equal the room reheat minimum setting.

Note that shutting off mechanical cooling does not shut off the cooling supply fan. If the fan schedule reads 1% or greater, the cooling supply fan will modulate accordingly, supplying untreated return/outside air to the cold deck side of the mixing boxes that are open.

System Options

1. The value of minimum outside air nominally follows the outside air schedule. The amount of outside air introduced into the ROA deck may be greater than the ventilation minimum if an outside air economizer or nighttime purge is activated this hour.

In addition, the amount of outside air brought into a particular room is a function of how much cold deck air is needed by the room. If, for example, the drift temperature is below the cooling thermostat, the cold deck is closed and no outside air can be admitted (unless a reheat minimum has been specified). When the drift temperature is above the cooling thermostat, a proportional amount of outside air is admitted into the space.

2. If the main cooling fan is scheduled at zero percent for a particular hour, no ventilation airflow can be delivered to any of the rooms.

3. Supply air temperature reset can be defined using the temperature control in the controls tab of the system properties.

4. A reheat minimum will determine the minimum amount of cold deck air that is delivered into the space each hour.

Application Notes:

● While supply air temperature reset control of the cold deck can save mechanical cooling energy, the room humidity may be higher and the central VAV fan may consume more energy.

● Humidity compensated controls can be implemented by using the humidity controller on the controls tab of the system properties to modify the default settings. By using the option supply air reset per maximum, for example, whenever a room relative humidity is greater than the design room relative humidity, the room's VAV dampers will continue to open until the room relative humidity is lowered to the design room relative humidity.

Alternatively, by specifying the option supply air reset per multizone maximum avg, whenever the return air relative humidity is greater than the design system relative humidity (which is the average of the design room relative humidities for the zones served by the system), supply air reset controls are deactivated and the main cooling coil leaving air temperature is depressed to its design value for that hour.

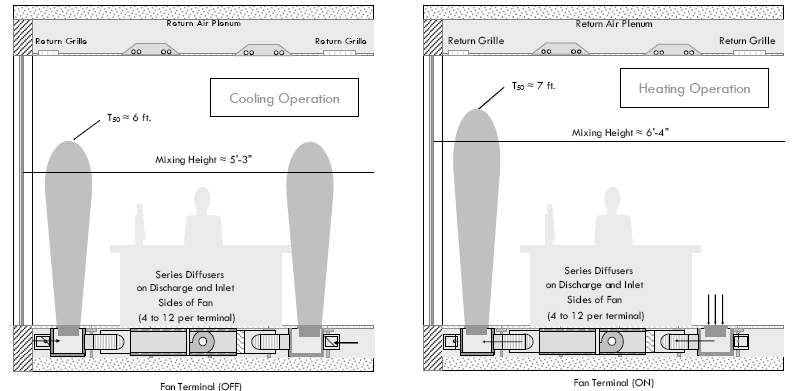

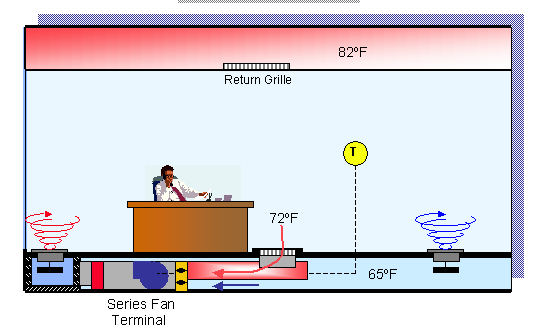

Series Fan-Powered VAV

The design is block air and block cooling capacity. The system is composed of a central VAV fan located on the cold deck which supplies cold air to series fan-powered (FP) boxes located in each room. Air from the central VAV fan is mixed with plenum air at the FP unit. The FP unit delivers air to the space at a constant volume. If heat is required in the space, a reheat coil located at the terminus of the FP box will activate to meet the extra heating load.

System Simulation

A constant volume of air is delivered to each room as long as both the main cooling and main heating fans are scheduled on. Once the drift temperature is known for all rooms this hour, the program calculates the supply air temperature and the proportions of cold and runaround deck air required by each room. When the room drift temperature has risen above the room cooling thermostat, cool air from the cold deck side of the FP unit opens and mixes with warm air from the runaround deck side of the FP unit such that the mixture temperature is sufficient to meet the cooling load. When the room drift temperature drops below the room heating thermostat, the reheat coil in the FP unit is energized, heating the supply air to a temperature which will maintain the space at the heating thermostat temperature. When the drift temperature is in the dead band, only untreated plenum air is admitted to the space.

System Options

1. The value of minimum room outside air airflow nominally follows the outside air schedule. The amount of outside air brought into the cold deck side of the room mixing box may be greater than the minimum if an outside air economizer or nighttime purge is activated this hour.

The quantity of outside air brought into the cold deck side of the mixing box may be less than the minimum if the cooling load for an individual room calls for cooling airflow less than the minimum ventilation airflow. In either the heating-only mode or in the deadband temperature range, no outside air can be delivered to the room (unless a reheat minimum has been input).

Single Zone Variable Air Volume

This system consists of a variable volume fan, a DX cooling coil and a heating coil (usually electric resistance heat) and serves a single zone. The coils and fan are therefore located at the zone level, meaning that a separate Single Zone VAV (SZVAV) unit will be created for each zone attached to that system type. If a given zone is comprised of several rooms, this system is typically controlled by a single thermostat located in one of the rooms. This means that all the rooms get the same supply airflow fraction and supply air temperature as the “control” room.

Each zone assigned to this system will be given its own set of coils. For example, if 10 zones are assigned to an individual Single Zone VAV system, 10 systems will be created, one per zone.

Supply Airflow/Temperature Control

For Single Zone VAV, the cooling supply air temperature each time step will default to the design cooling supply air dry bulb (SADBC), i.e., the program assumes that the hourly SADBC Setpoint = Design SADBC for the entire year. This default value can be altered by using Supply Air Reset controls on the controls tab in the system properties.

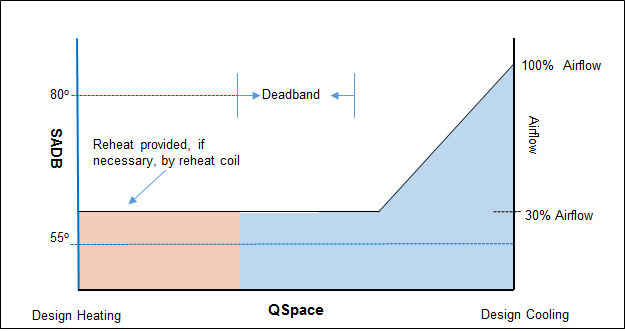

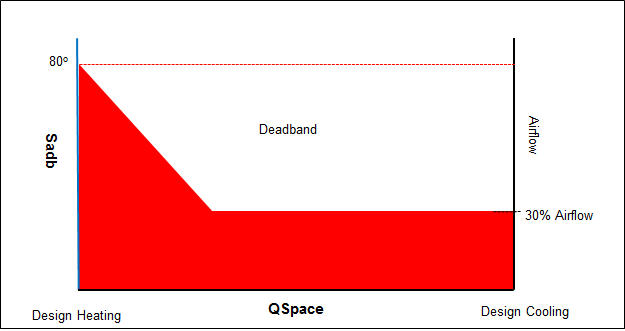

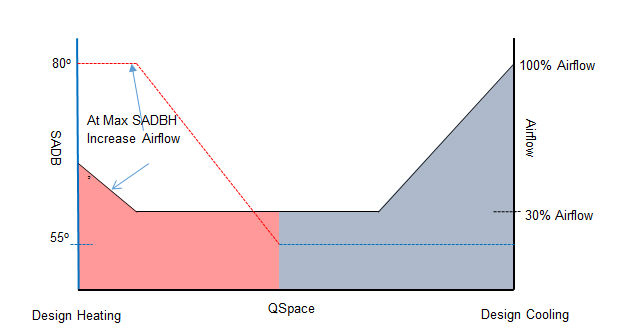

The minimum cooling airflow defaults to 30% and can be overridden by changing the VAV Minimum Cooling Airflow value on the terminal device tab of the system properties. In cooling mode, the supply air dry bulb is fixed while the supply airflow is varied to match the load. While the thermostat signal is in the deadband region (essentially, no load condition), the Single Zone VAV unit will continue to deliver minimum airflow at the SADBC setpoint. However, once the control thermostat senses that the room temperature has fallen below the heating thermostat setpoint, the cooling coil is deactivated and the heating coil becomes active. In heating mode, the supply airflow is maintained at its minimum setting and SADBH is varied to meet the space load. However, once the supply air dry bulb heating has reached its maximum (design) value, the airflow is increased to match the space load. The maximum heating-mode airflow is based on the VAV Minimum Heating Airflow value defined on the terminal device tab of the system properties. The control scheme over the range of space loads is shown in the diagram below.

Design Considerations

Since the Single Zone VAV air handler and coils are located at the zone level, the design cooling airflow is block at the zone level. This means that the total cooling design airflow across the system is the sum of the zone block airflows rather than the block airflow at the time of the system block. The system checksums will display the sum of the zone block airflows (collection of zone-level fans) rather than the system block airflow (which would only be correct if the fan were at the system level).

DesignClgSupplyAirflowzn = QBlockClgSpaceSensiblezn / [k * (DsRmdbc – SADBC)]

DesignClgSupplyAirflowsys = ∑DesignClgSupplyBlockAirflowzn

The zone design heating airflow will equal the sum of the design VAV heating airflows (the VAV maximum heating airflow setting as defined on the Create Room – Airflows screen). However, if the VAV maximum heating airflow value has not been defined, the VAV minimum cooling airflow is used instead. The maximum heating for a room occurs when the heating airflow and SADB are both at their maximums. If the AHU serves more than one room, the design heating supply airflow is the sum of the maximum heating supply airflows from the attached rooms:

DesignHtgSupplyAirflowzn = ∑MaxHtgSupplyAirflowrm

The system checksums represents the sum of the zone AHU’s and so will need to display the sum-of-the peak zone heating airflows (which also equals the sum-of-the-peak room heating design airflows).

DesignHtgSupplyAirflowsys = ∑ DesignHtgSupplyAirflowzn

The zone AHU’s design heating supply air dry bulb is based on the largest SADBH required after scanning all the rooms attached to a particular zone. First, the required SADBHrm is calculated for each room based on that room’s design supply heating airflow, design space sensible heating load, and DsRmdbhrm:

SADBHrm = DsRmdbhrm - QHtgSpaceSensRequiredrm / [k * DesignHtgSupplyAirflowrm]

Then the highest of these values is used to set the design value of SADBH for the zone-level AHU.

SADBHzn = Largest of [SADBHrm] for rooms attached to this zone

The design heating capacity is determined by first calculating the entering coil condition at the winter design condition:

Cedbhzn =[ (DesignHtgSupplyAirflowzn – DesignVentAirflowz) * Radbh + DesignVentAirflow*TVentDeckLvg] / DesignHtgSupplyAirflow

The zone-level AHU’s heating capacity is then given by:

QMainHtgCapacityzn = k * DesignHtgSupplyAirflowzn * (SADBHzn - Cedbhzn)

Because the SADBHzn is determined by finding the highest SADBHrm from all the rooms attached to that zone AHU, a net space sensible oversizing occurs for the rooms whose required SADBHrm was less than SADBHzn:

QHtgSpaceSensActualrm = k * DesignHtgSupplyAirflowrm * (SADBHzn – Cedbhrm)

QHtgSpaceSensOversizing = QHtgSpaceSensRequiredrm – QHtgSpaceSensActualrm

= k * DesignHtgSupplyAirflowrm * (SADBHrm – SADBHzn)

Zoning Considerations

Since the Single Zone VAV system does not have reheat coils at the room terminal units and because the thermostat sensor is typically located in just one of the rooms attached to the zone-level AHU, all rooms will receive the same temperature and supply airflow fraction as the “control” room. Therefore, it is extremely important to assign rooms with similar thermal loading to their parent zone-level AHU, i.e., the attached rooms facades (if any) should face the same direction and have nearly identical internal load schedules and load/floor area. Wild room temperature swings can occur if the control room’s thermal profile is not similar to the other attached rooms. Of course, if an AHU is assigned to each room, i.e., each room is its own zone, this consideration becomes moot.

Simulation notes

The program simulation is modeled in hour increments which can cause “non-reality” incidents. For example, the cooling coil would normally deactivate when the thermostat falls below the heating thermostat; however, if the introduction of minimum cooling airflow is the cause of the room temperature falling below the heating thermostat, the cooling coil will be off for part of the hour which is modeled by calculating an average SADBC for the hour instead of forcing DsnSADBC the entire hour.

Variable Refrigerant Flow

A typical Heat Recovery type Variable Refrigerant Flow (VRF) system consists of one outdoor unit and multiple indoor units. The compressor in this system is variable speed and controls the flow of refrigerant to the indoor units. A heat recovery VRF system has three modes of operation - Cooling only, Simultaneous heating and cooling and Heating only.

Indoor Unit

The indoor unit is essentially a DX fan coil. It consists of one DX coil and a three speed fan. Fan speeds are designated as H (100% airflow), L (70% airflow) and LL (10% airflow). The fan operates at minimum speed during the heating mode. Indoor units are typically unducted however. There are two models that can handle small duct systems (up to 300 Pa). The indoor unit is piped to a branch selector. This branch selector controls the flow of refrigerant to the fan coil unit. If the fan coil calls for cooling, the branch selector sends liquid refrigerant to the fan coil and the fan coil acts like an evaporator. If the fan coil calls for heating, then the branch selector sends hot gas to the fan coil and the fan coil acts like a condenser.

Since the branch selector controls the refrigerant flow and it always has access to both hot gas (for heating) and liquid refrigerant (for cooling) the fan coil is able to switch between heating and cooling mode very quickly. Indoor units can handle up to 10% outside air. Any additional ventilation requirements must be handled by an optional ventilation unit.

Each indoor unit has its own thermostat to control space conditions. Typical supply air temperatures for the indoor unit are 50°F in cooling and 100°F in heating. An optional electric or hot water coil can be added to the unit.

Airside simulation

When the room drift temperature rises above the cooling thermostat, the cooling coil is engaged at a constant cooling supply air temperature for the a percentage of the hour that it takes to bring the room temperature down to the cooling thermostat temperature. This heat is rejected to the refrigerant condenser loop. For the portion of the hour that the cooling coil is de-energized, the supply air will remain at the return/outside air dry bulb temperature (plus fan heat).

When the room drift temperature drops below the heating thermostat, the heating coil is engaged at a constant heating supply air temperature for the a percentage of the hour that it takes to bring the room temperature up to the heating thermostat temperature. The indoor unit will remove heat from the refrigerant condenser loop. For the portion of the hour that the cooling coil is de-energized, the supply air will remain at the return/outside air dry bulb temperature (plus fan heat).

Outdoor Unit

The outdoor unit consists of two condenser coils, two condenser fans, a variable speed compressor, and a reversing valve. The compressor operation is controlled by suction pressure. When operating in Cooling mode, the compressor speed varies to maintain a constant evaporator pressure. When operating in Heating mode, the compressor speed varies to maintain constant condensing pressure.

The operating mode of the condensing unit is controlled by the net load on the system. For example, if the net load on the system is cooling (cooling load + heating load = net cooling load) the unit operates in cooling mode and follows the primary unloading curve. Similarly, if the net load on the system is heating (cooling load + heating load = net heating load) the unit operates in heating mode and follows the secondary unloading curve. In all cases, the compressor capacity will modulate to exactly match the load on the system.

Variable Volume Reheat

VAV RH (30% Min Flow Default)

Variable Volume Reheat (30% Min Flow Default)

Note, there are two versions of this system:

● VAV RH (30% Min Flow Default) (DX): Variable Volume Reheat (30% Min Flow Default) (Direct Expansion)

● VAV RH (30% Min Flow Default) (CW): Variable Volume Reheat (30% Min Flow Default) (Chilled Water)

The only difference between these two systems is the Direct Expansion version uses a direct expansion cooling coil whereas the Chilled Water version uses a chilled water cooling coil.

The design is block cooling capacity and block air. This system is composed of a central VAV fan located on the cold deck that supplies conditioned air to each room's VAV box. The individual rooms may see a variable air quantity depending upon the cooling load and the minimum room airflow setting. A reheat coil in each VAV box is available to reheat the conditioned air if necessary at part load conditions. Return air is drawn from a common return air plenum where loads to return air are picked up from all rooms and brought back to the ROA deck for mixing with outside air.

System Simulation

For the case when no minimum stops exist, the following events will occur. When the drift temperature rises above this hour's cooling thermostat set point, the VAV box opens and delivers a proportionate quantity of supply air to the space, i.e., only enough cool supply air is added to bring down and maintain the room at this hour's cooling thermostat setpoint. When the drift temperature falls below this hour's heating thermostat setpoint, the VAV box is fully closed and neither heating nor cooling is possible by the main system since no supply airflow is available. As long as the room drift temperature is below the cooling thermostat setpoint this hour, the VAV box is fully closed. While the drift temperature is within the deadband region, there is no air movement and absolutely no mechanical heating or cooling can occur in the room by the main system.

For the case where minimum stops exist, the sequence of events is as follows. The VAV box is initially fixed at the reheat minimum airflow setting. Introduction of this cool air will drive the room temperature downward if the space cooling load is not great enough. The reheat coil will be energized only if the room temperature starts dropping below this hour's heating thermostat set point. If the admittance of this minimum quantity of conditioned air does not bring the room temperature below the cooling thermostat during times of high sensible load, the VAV box is opened past the minimum stop position until there is adequate cooling airflow to satisfy the cooling load.

Note that shutting off mechanical cooling does not shut off the VAV supply fan; if the fan schedule reads 1% or greater the supply fan will modulate accordingly, supplying untreated return/outside air to the terminal boxes that are open. However, if the supply fan is scheduled off for a particular hour, no mechanical cooling or mechanical heating is possible.

System Options

1. The value of minimum outside air nominally follows the outside air schedule. The amount of outside air introduced into the ROA deck may be greater than the ventilation minimum if an outside air economizer or nighttime purge is activated this hour.

In addition, the amount of outside air brought into a particular room is a function of how much cold deck air is needed by the room. If, for example, the drift temperature is below the cooling thermostat, the cold deck is closed and no outside air can be admitted (unless a reheat minimum has been specified). When the drift temperature is above the cooling thermostat, a proportional amount of outside air is admitted into the space.

If the main cooling fan is scheduled at zero percent for a particular hour, no ventilation airflow can be delivered to any of the rooms.

2. The cooling supply fan (entered as the main cooling fan) is available whenever the schedule reads 1% or greater. Its energy consumption will be proportional to the system cooling load for that hour. The supply fan may not be duty cycled during the cooling mode.

3. Specifying fan cycling on the availability manager tab of the system properties will allow the supply fan to cycle with the heating load for rooms which have minimum reheat airflow scheduled during unoccupied hours. Fan cycling can only apply to rooms that have a design reheat minimum airflow > 0 and their reheat minimum schedule reading > 0% for the hour(s) that the people schedule reads 5% or less.

4. Supply air temperature reset can be defined using the temperature control in the controls tab of the system properties.

5. Reheat Minimum. A reheat minimum will determine the minimum airflow into the space each hour. A reheat coil is assumed to be located at the terminus of each room's VAV box. A default value of 30% of the design room cooling airflow is assumed.

Application Notes

1. Warning: hours in which the reheat minimum is scheduled at 0%, no heating can take place.

2. While supply air reset control will save cooling energy, the room relative humidity will be higher and the VAV fan will consume more energy.

3. Humidity compensated controls can be implemented by using the humidity controller on the controls tab of the system properties to modify the default settings. By using the option supply air reset per maximum, for example, whenever a room relative humidity is greater than the design room relative humidity, the room's VAV dampers will continue to open until the room relative humidity is lowered to the design room relative humidity.

Alternatively, by specifying the option supply air reset per multizone maximum avg, whenever the return air relative humidity is greater than the design system relative humidity (which is the average of the design room relative humidities for the zones served by the system), supply air reset controls are deactivated and the main cooling coil leaving air temperature is depressed to its design value for that hour.

VAV w/ Baseboard Heating

The design is block tons and block air. This system is composed of a variable volume fan located on the cold deck that supplies conditioned air to each room's VAV box. The individual rooms see a variable air quantity proportional to the cooling load. Return air is drawn from a common return air plenum where loads to return air are picked up from all rooms and brought back to the ROA deck for mixing with outside air.

System Simulation

For the case when no minimum stops exist, the following events will occur. When the drift temperature rises above this hour's cooling thermostat set point, the VAV box opens and delivers a proportionate quantity of supply air to the space, i.e., only enough cool supply air is added to bring down and maintain the room at this hour's cooling thermostat setpoint. When the drift temperature falls below this hour's heating thermostat setpoint, the heating load is handled by a radiation heating unit that responds to the room thermostat, i.e., enough heat is added to the space to bring up and maintain the room at the heating thermostat set point. As long as the room drift temperature is below the cooling thermostat setpoint this hour, the VAV box is fully closed. While the drift temperature is within the dead band region, there is no air movement and absolutely no heating or cooling can take place within the room.

For the case where reheat minimums exist, the sequence of events is as follows. The VAV box is initially fixed at the reheat minimum airflow setting. Introduction of this cool air may drive the room temperature downward if the cooling load is low enough. The radiation heating unit will be energized only if the room temperature starts dropping below this hour's heating thermostat setpoint. If the admittance of this minimum quantity of conditioned air does not bring the room temperature below the cooling thermostat during times of high sensible load, the VAV box is opened past the minimum stop position until there is adequate cooling airflow to satisfy the load.

Note that shutting off mechanical cooling does not shut off the VAV supply fan; if the fan schedule reads 1% or greater the supply fan will modulate accordingly, supplying untreated return/outside air to the terminal boxes that are open. However, if the supply fan is scheduled off for a particular hour, no mechanical cooling is possible.

System Options

1. The value of minimum outside air nominally follows the outside air schedule. The amount of outside air introduced into the ROA deck may be greater than the ventilation minimum if an outside air economizer or nighttime purge is activated this hour.

In addition, the amount of outside air brought into a particular room is a function of how much cold deck air is needed by the room. If, for example, the drift temperature is below the cooling thermostat, the cold deck is closed and no outside air can be admitted (unless a reheat minimum has been specified). When the drift temperature is above the cooling thermostat, a proportional amount of outside air is admitted into the space.

If the main cooling fan is scheduled at zero percent for a particular hour, no ventilation airflow can be delivered to any of the rooms.

2. The cooling supply fan (entered as the main cooling fan) is available whenever the schedule reads 1% or greater. Its energy consumption will be proportional to the system cooling load for that hour. The supply fan may not be duty cycled during the cooling mode.

3. Specifying fan cycling on the availability manager tab of the system properties will allow the supply fan to cycle with the heating load for rooms which have minimum reheat airflow scheduled during unoccupied hours. Fan cycling can only apply to rooms that have a design reheat minimum airflow > 0 and their reheat minimum schedule reading > 0% for the hour(s) that the people schedule reads 5% or less.

4. Supply air temperature reset can be defined using the temperature control in the controls tab of the system properties.

5. Reheat Minimum. A reheat minimum will determine the minimum airflow into the space each hour. A reheat coil is assumed to be located at the terminus of each room's VAV box. A default value of 30% of the design room cooling airflow is assumed.

Application Notes

● While supply air reset control will save cooling energy, the room relative humidity will be higher and the VAV fan will consume more energy.

● The shutoff VAV system is almost identical to the Variable Air Volume Reheat (VRH) system except that VAV assumes radiation heating (with no reheat minimum) while VRH uses a reheat coil (with a 30% reheat minimum) for heating.

● Humidity compensated controls can be implemented by using the humidity controller on the controls tab of the system properties to modify the default settings. By using the option supply air reset per maximum, for example, whenever a room relative humidity is greater than the design room relative humidity, the room's VAV dampers will continue to open until the room relative humidity is lowered to the design room relative humidity.

Alternatively, by specifying the option supply air reset per multizone maximum avg, whenever the return air relative humidity is greater than the design system relative humidity (which is the average of the design room relative humidities for the zones served by the system), supply air reset controls are deactivated and the main cooling coil leaving air temperature is depressed to its design value for that hour.

Zone HVAC

VAV PTAC

The design is block air and block cooling capacity.

A separate cooling/heating heat pump is located in each zone. Each unit can draw return air either from a return air plenum above the particular room (return air assignments greater than zero) or recirculate air within the room (return air assignments are zero). The design cooling and heating supply air temperatures user input. The fans are variable volume.

System Simulation

When the room drift temperature rises above the room cooling thermostat, the cooling coil is energized (at a constant cooling supply air temperature) for a percentage of the hour that it takes to bring the room temperature down to the cooling thermostat temperature. This heat is rejected to the condenser loop. For the portion of the hour that the cooling coil is de-energized, the supply air will remain at the return/outside air dry bulb temperature (plus supply fan heat).

When the room drift point temperature drops below the room heating thermostat, the heating coil is energized (at a constant heating supply air temperature) for a percentage of the hour that it takes to bring the room temperature up to the heating thermostat temperature. The heat pump will remove heat from the condenser loop, thereby lowering its temperature. For the portion of the hour that the heating coil is de-energized, the supply air will remain at the return/outside air dry bulb temperature (plus supply fan heat).

When the room drift temperature lies within the deadband, the supply air will initially remain at the return/outside air dry bulb (plus fan heat).

System Options

1. The value of minimum ventilation airflow will be proportional to the percentage defined by the outside air schedule. The value of outside airflow may be greater than the nominal value if an economizer or nighttime purge is activated.

2. The value of outside airflow may be less than the nominal ventilation value if the supply fan (entered as the main cooling fan) has been scheduled at less than 100%; the outside air percentage for a particular hour will be multiplied by the main cooling fan utilization percent for that hour. If the supply fan has been scheduled off for a particular hour, no outside air can be delivered to the rooms.

3. The supply fan is available whenever the schedule reads 1% or greater. Its energy consumption will be proportional to the system cooling load for that hour. The minimum cooling airflow defaults to 30% and can be overridden by changing the VAV Minimum Cooling Airflow value on the Create Room – Airflows screen. In cooling mode, the supply air dry bulb is fixed while the supply airflow is varied to match the load. While the thermostat signal is in the deadband region (essentially, no load condition), the unit will continue to deliver minimum airflow at the SADBC setpoint. However, once the control thermostat senses that the room temperature has fallen below the heating thermostat setpoint, the cooling coil is deactivated and the heating coil becomes active. In heating mode, the supply airflow is maintained at its minimum setting and SADBH is varied to meet the space load. However, once the supply air dry bulb heating has reached its maximum (design) value, the airflow is increased to match the space load. The maximum heating mode airflow is based on the VAV Minimum Heating Airflow value defined on the Create Rooms – Airflows screen.

4. Neither the cooling or heating supply air temperature may be reset using supply air reset controls since the cooling supply air temperature is cycled at a constant temperature and the heating supply air temperature responds to the room thermostat.

Application Notes

● For PTHP systems, the unit can be oversized to include a safety factor by entering the cooling design capacity and heating design capacity (on the sizing tab of the system properties) as something larger than 100% of design cooling or heating capacity respectively.

● If the fans are to be cycled during unoccupied hours, enter the fan cycling information on the availability manager tab in the system properties.

VAV Unit Ventilator

A separate unit ventilator, including air handler and heating coil, is located in each room (on the hot deck at the room level). The design heating supply air temperature is assumed to be 95°F unless overridden by user input to the Airflow Design Temperatures screen.

System Simulation

The supply fan follows the main heating fan schedule in a time-clock fashion, bringing in outside air through the main heating coil according to the ventilation schedule.

When the room drift temperature rises above the room heating thermostat, the heating coil is de-activated, allowing the space temperature to drift upward. Since the supply air will be at the return/outside air dry bulb temperature (plus fan heat), scheduling outside air into the space will temper this effect to some degree.

When the room drift temperature drops below the room heating thermostat, the heating coil is modulated to produce a supply air dry bulb that will bring the room temperature up to the heating thermostat temperature.

System Options

1. The value of minimum ventilation airflow will be proportional to the percentage defined by the outside air schedule. The value of outside airflow may be greater than the nominal value if an economizer is activated.

The value of outside airflow may be less than the nominal ventilation value if the supply fan (entered as the main cooling fan) has been scheduled at less than 100%; the outside air percentage for a particular hour will be multiplied by the main heating fan utilization percent for that hour. If the supply fan has been scheduled off for a particular hour, no outside air can be delivered to the rooms.

2. The supply fan is available whenever the schedule reads 1% or greater. Its energy consumption will be proportional to the system cooling load for that hour. The minimum cooling airflow defaults to 30% and can be overridden by changing the VAV Minimum Cooling Airflow value on the Create Room – Airflows screen. In cooling mode, the supply air dry bulb is fixed while the supply airflow is varied to match the load. While the thermostat signal is in the deadband region (essentially, no load condition), the unit will continue to deliver minimum airflow at the SADBC setpoint. However, once the control thermostat senses that the room temperature has fallen below the heating thermostat setpoint, the cooling coil is deactivated and the heating coil becomes active. In heating mode, the supply airflow is maintained at its minimum setting and SADBH is varied to meet the space load. However, once the supply air dry bulb heating has reached its maximum (design) value, the airflow is increased to match the space load. The maximum heating mode airflow is based on the VAV Minimum Heating Airflow value defined on the Create Rooms – Airflows screen.

Application Notes

● If the fans are to be cycled during unoccupied hours, enter the fan cycling information on the availability manager tab in the system properties.

● Internal rooms (rooms with no walls, roofs, etc.) should be provided with adequate outside air if internal loads are scheduled; otherwise, the room temperature may go out of control.

● Since the ventilation air brought into the space will create "positive" building pressure, it is suggested that infiltration be scheduled opposite the outside air schedule, e.g., for outside air scheduled at 40% for a particular hour, the infiltration schedule should read (100-40) = 60%.

VAV Fan Coil

The design is block air and block cooling capacity.

A separate fan coil unit, including air handler and cooling and heating coils, is assumed for each zone. Central heating and cooling plants are assumed to handle the heating and cooling coil loads. Plenum return air loads are allowed although the assumption is that the return air is pulled from above the individual zones. If the fan coils are floor mounted units the lighting return air assignments should be set at zero. The design cooling and heating supply air temperatures are determined from either the Design Phase or user input and cannot be overridden by outside air reset schedules. The fans are variable volume.

System Simulation

When the zone drift temperature rises above the room cooling thermostat, the cooling coil is modulated to produce a supply air dry bulb that will bring the space down to the cooling thermostat temperature.

When the room drift temperature drops below the room heating thermostat, the heating coil is modulated to produce a supply air dry bulb that will bring the room temperature up to the heating thermostat temperature.

When the room drift temperature lies within the deadband, the supply air will be at the return/outside air dry bulb temperature (plus fan heat). If necessary, the return/outside air mixture will be heated or cooled to prevent the room temperature from going out of the deadband because of the introduction of significant quantities of cold or hot ventilation air.

System Options

1. The value of minimum ventilation airflow will be proportional to the percentage defined by the outside air schedule. The value of outside airflow may be greater than the nominal value if an economizer or nighttime purge is activated.

The value of outside airflow may be less than the nominal ventilation value if the supply fan (entered as the main cooling fan) has been scheduled at less than 100%; the outside air percentage for a particular hour will be multiplied by the main cooling fan utilization percent for that hour. If the supply fan has been scheduled off for a particular hour, no outside air can be delivered to the rooms.

2. The supply fan is available whenever the schedule reads 1% or greater. Its energy consumption will be proportional to the system cooling load for that hour. The minimum cooling airflow defaults to 30% and can be overridden by changing the VAV Minimum Cooling Airflow value on the Create Room – Airflows screen. In cooling mode, the supply air dry bulb is fixed while the supply airflow is varied to match the load. While the thermostat signal is in the deadband region (essentially, no load condition), the unit will continue to deliver minimum airflow at the SADBC setpoint. However, once the control thermostat senses that the room temperature has fallen below the heating thermostat setpoint, the cooling coil is deactivated and the heating coil becomes active. In heating mode, the supply airflow is maintained at its minimum setting and SADBH is varied to meet the space load. However, once the supply air dry bulb heating has reached its maximum (design) value, the airflow is increased to match the space load. The maximum heating mode airflow is based on the VAV Minimum Heating Airflow value defined on the Create Rooms – Airflows screen.

3. Since the fan coil heating and cooling supply air temperatures respond to the room thermostat, supply air reset control is not possible.

Application Notes

● The program assumes that the fan coil system is four-pipe (heating and cooling available all year round). To input a two-pipe fan coil system, the user should indicate which months the heating and cooling functions are to be locked out when creating the main cooling and heating schedules.

● If the fans are to be cycled during unoccupied hours, enter the fan cycling information on the availability manager tab in the system properties.

VAV PTHP

The design is block air and block cooling capacity.

A separate cooling/heating heat pump is located in each zone. Each unit can draw return air either from a return air plenum above the particular room (return air assignments greater than zero) or recirculate air within the room (return air assignments are zero). The design cooling and heating supply air temperatures are determined from either the Design Phase or user input and cannot be overridden by outside air reset schedules. The fans are variable volume.

System Simulation

When the room drift temperature rises above the room cooling thermostat, the cooling coil is energized (at a constant cooling supply air temperature) for a percentage of the hour that it takes to bring the room temperature down to the cooling thermostat temperature. This heat is rejected to the condenser loop. For the portion of the hour that the cooling coil is de-energized, the supply air will remain at the return/outside air dry bulb temperature (plus supply fan heat).

When the room drift point temperature drops below the room heating thermostat, the heating coil is energized (at a constant heating supply air temperature) for a percentage of the hour that it takes to bring the room temperature up to the heating thermostat temperature. The heat pump will remove heat from the condenser loop, thereby lowering its temperature. For the portion of the hour that the heating coil is de-energized, the supply air will remain at the return/outside air dry bulb temperature (plus supply fan heat).

When the room drift temperature lies within the deadband, the supply air will initially remain at the return/outside air dry bulb (plus fan heat).

System Options

1. The value of minimum ventilation airflow will be proportional to the percentage defined by the outside air schedule. The value of outside airflow may be greater than the nominal value if an economizer or nighttime purge is activated.

The value of outside airflow may be less than the nominal ventilation value if the supply fan (entered as the main cooling fan) has been scheduled at less than 100%; the outside air percentage for a particular hour will be multiplied by the main cooling fan utilization percent for that hour. If the supply fan has been scheduled off for a particular hour, no outside air can be delivered to the rooms.

2. The supply fan is available whenever the schedule reads 1% or greater. Its energy consumption will be proportional to the system cooling load for that hour. The minimum cooling airflow defaults to 30% and can be overridden by changing the VAV Minimum Cooling Airflow value on the Create Room – Airflows screen. In cooling mode, the supply air dry bulb is fixed while the supply airflow is varied to match the load. While the thermostat signal is in the deadband region (essentially, no load condition), the unit will continue to deliver minimum airflow at the SADBC setpoint. However, once the control thermostat senses that the room temperature has fallen below the heating thermostat setpoint, the cooling coil is deactivated and the heating coil becomes active. In heating mode, the supply airflow is maintained at its minimum setting and SADBH is varied to meet the space load. However, once the supply air dry bulb heating has reached its maximum (design) value, the airflow is increased to match the space load. The maximum heating mode airflow is based on the VAV Minimum Heating Airflow value defined on the Create Rooms – Airflows screen.

3. Neither the cooling or heating supply air temperature may be reset using supply air reset controls since the cooling supply air temperature is cycled at a constant temperature and the heating supply air temperature responds to the room thermostat.

Application Notes

● For PTHP systems, the unit can be oversized to include a safety factor by entering the cooling design capacity and heating design capacity (on the sizing tab of the system properties) as something larger than 100% of design cooling or heating capacity respectively.

● If the fans are to be cycled during unoccupied hours, enter the fan cycling information on the availability manager tab in the system properties.

VAV WSHP

The design is block air and block cooling capacity.

A separate WSHP unit is assumed for each room. Each unit can draw return air either from a return air plenum above the particular room or recirculate air within the room. The fans are variable volume.

In the heating mode, the evaporative coil acts as a condenser coil by drawing heat from the condenser loop. If not enough heat is available from the condenser loop, i.e., if the loop temperature has dropped below 60 F, a backup heat source (electric, gas, oil, etc.) is assumed to provide sufficient heat to the condenser loop. In the cooling mode, condenser heat is rejected to the loop. If the loop temperature exceeds 90 F, the heat is rejected to a closed loop cooling tower.

System Simulation

When the room drift temperature rises above the room cooling thermostat, the cooling coil is energized (at a constant cooling supply air temperature) for a percentage of the hour that it takes to bring the room temperature down to the cooling thermostat temperature. This heat is rejected to the condenser loop. For the portion of the hour that the cooling coil is de-energized, the supply air will remain at the return/outside air dry bulb temperature (plus supply fan heat).

When the room drift temperature drops below the room heating thermostat the heating coil is energized (at a constant heating supply air temperature) for a percentage of the hour that it takes to bring the room temperature up to the heating thermostat temperature. The heat pump will remove heat from the condenser loop, thereby lowering its temperature. For the portion of the hour that the heating coil is de-energized, the supply air will remain at the return/outside air dry bulb temperature (plus supply fan heat).

When the room drift temperature lies within the deadband, the supply air will initially remain at the return/outside air dry bulb temperature (plus supply fan heat).

System Options

1. The value of minimum ventilation airflow will be proportional to the percentage defined by the outside air schedule. The value of outside airflow may be greater than the nominal value if an economizer or nighttime purge is activated.

The value of outside airflow may be less than the nominal ventilation value if the supply fan has been scheduled at less than 100%; the outside air percentage for a particular hour will be multiplied by the main cooling fan utilization percent for that hour. If the supply fan has been scheduled off for a particular hour, no outside air can be delivered to the rooms.

2. The supply fan is available whenever the schedule reads 1% or greater. Its energy consumption will be proportional to the system cooling load for that hour. The minimum cooling airflow defaults to 30% and can be overridden by changing the VAV Minimum Cooling Airflow value on the Create Room – Airflows screen. In cooling mode, the supply air dry bulb is fixed while the supply airflow is varied to match the load. While the thermostat signal is in the deadband region (essentially, no load condition), the unit will continue to deliver minimum airflow at the SADBC setpoint. However, once the control thermostat senses that the room temperature has fallen below the heating thermostat setpoint, the cooling coil is deactivated and the heating coil becomes active. In heating mode, the supply airflow is maintained at its minimum setting and SADBH is varied to meet the space load. However, once the supply air dry bulb heating has reached its maximum (design) value, the airflow is increased to match the space load. The maximum heating mode airflow is based on the VAV Minimum Heating Airflow value defined on the Create Rooms – Airflows screen.

Application Notes

● Although the equipment configuration is different, the airside simulation of water source heat pump (WSHP) and packaged terminal air conditioners (PTAC) is similar.

● For WSHP systems, the unit can be oversized to include a safety factor by entering the cooling design capacity and heating design capacity (on the sizing tab of the system properties) as something larger than 100% of design cooling or heating capacity respectively.

● Humidity compensated controls can be implemented by using the humidity controller on the controls tab of the system properties to modify the default settings. By using the option supply air reset per maximum, for example, whenever a room relative humidity is greater than the design room relative humidity, the room's VAV dampers will continue to open until the room relative humidity is lowered to the design room relative humidity.

Alternatively, by specifying the option supply air reset per multizone maximum avg, whenever the return air relative humidity is greater than the design system relative humidity (which is the average of the design room relative humidities for the zones served by the system), supply air reset controls are deactivated and the main cooling coil leaving air temperature is depressed to its design value for that hour.

Radiant

VAV Heated Floor

The system is composed of high temperature radiant heating panels in the floor of the space and has no mechanical cooling capabilities.

System Simulation

When the room drift temperature falls below the hourly heating thermostat, the heat source is activated to maintain the room at the heating thermostat temperature. When the drift temperature rises above the room heating thermostat, the room temperature is allowed to drift upward.

System Options

1. Outside air is brought into the space via a separate outside air system. The value of minimum outside air airflow will be proportional to the percentage defined by the outside air schedule. Economizer controls are not available to the Heated Floor system; however, opening and shutting of windows can be simulated (even if there are no external walls) by specifying a dry bulb economizer type and scheduling the economizer available during occupied hours.

2. The only fan allowed to operate is the optional ventilation fan which will follow the outside air schedule in time clock fashion, i.e., if the schedule reads 80% for a particular hour, the fan will operate at full rpm for 80% of the hour and remain off the rest of the hour.

3. Reset Schedule. The radiation system responds only to the room heating thermostat and will thus ignore any OA reset schedule.

Application Notes

● If radiant panels are used as the heat source, the user should set back the heating thermostat several degrees from normal (for example, from 68 to 65 F) since radiant panels are able to maintain an equivalent comfort level at a lower room air temperature.

● Internal rooms (no walls, roofs, etc.) should be provided with adequate outside air to temper the room temperature if internal loads are scheduled; otherwise, the room temperature may go out of control.

● Since the ventilation air brought into the room will create "positive" building pressure, it is suggested that infiltration be scheduled opposite the outside air schedule, e.g., for outside air scheduled at 40% for a particular hour, the infiltration schedule should read (100 - 40) = 60%.

● A radiation system can support a plenum, but any loads assigned to return air will be conducted back out through the ceiling and any external plenum (wall and roof) surface areas.

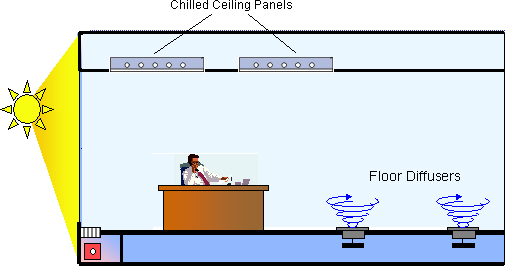

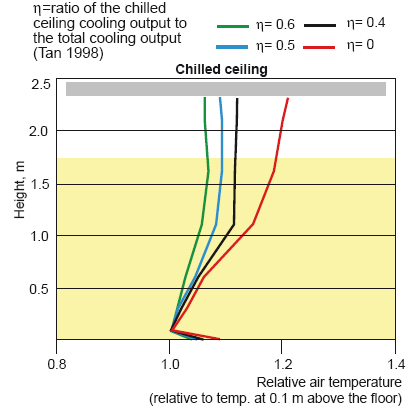

VAV Chilled Ceiling

The system is composed of radiant panels in the ceiling of the space and has no mechanical heating capabilities.

System Simulation

When the room drift temperature rises above the hourly heating thermostat, the cooling panels are activated to maintain the room at the cooling thermostat temperature. When the drift temperature falls below the room cooling thermostat, the room temperature is allowed to drift upward.

System Options

1. Outside air is brought into the space via a separate outside air system. The value of minimum outside air airflow will be proportional to the percentage defined by the outside air schedule. Economizer controls are not available to the radiant cooling system; however, opening and shutting of windows can be simulated (even if there are no external walls) by specifying a dry bulb economizer type and scheduling the economizer available during occupied hours.

2. The only fan allowed to operate is the optional ventilation fan which will follow the outside air schedule in time clock fashion, i.e., if the schedule reads 80% for a particular hour, the fan will operate at full rpm for 80% of the hour and remain off the rest of the hour.

3. Reset Schedule. The radiation system responds only to the room cooling thermostat and will thus ignore any OA reset schedule.

Application Notes

● Internal rooms (no walls, roofs, etc.) should be provided with adequate outside air to temper the room temperature if internal loads are scheduled; otherwise, the room temperature may go out of control.

● Since the ventilation air brought into the room will create "positive" building pressure, it is suggested that infiltration be scheduled opposite the outside air schedule, e.g., for outside air scheduled at 40% for a particular hour, the infiltration schedule should read (100 - 40) = 60%.

● A radiation system can support a plenum, but any loads assigned to return air will be conducted back out through the ceiling and any external plenum (wall and roof) surface areas.

Constant Volume (CV)

Each system type contains description of the system and its components.

Zone HVAC

CV Fan Coil

The design is peak air and block cooling capacity.

A separate fan coil unit, including air handler and cooling and heating coils, is assumed for each zone. Central heating and cooling plants are assumed to handle the heating and cooling coil loads. Plenum return air loads are allowed although the assumption is that the return air is pulled from above the individual zones. If the fan coils are floor mounted units the lighting return air assignments should be set at zero. The design cooling and heating supply air temperatures are determined from either the Design Phase or user input and cannot be overridden by outside air reset schedules. The fans are constant volume while the coils are modulated to meet the load.

System Simulation

When the zone drift temperature rises above the room cooling thermostat, the cooling coil is modulated to produce a supply air dry bulb that will bring the space down to the cooling thermostat temperature.

When the room drift temperature drops below the room heating thermostat, the heating coil is modulated to produce a supply air dry bulb that will bring the room temperature up to the heating thermostat temperature.

When the room drift temperature lies within the deadband, the supply air will be at the return/outside air dry bulb temperature (plus fan heat). If necessary, the return/outside air mixture will be heated or cooled to prevent the room temperature from going out of the deadband because of the introduction of significant quantities of cold or hot ventilation air.

System Options

1. The value of minimum ventilation airflow will be proportional to the percentage defined by the outside air schedule. The value of outside airflow may be greater than the nominal value if an economizer or nighttime purge is activated.

2. The value of outside airflow may be less than the nominal ventilation value if the supply fan (entered as the main cooling fan) has been scheduled at less than 100%; the outside air percentage for a particular hour will be multiplied by the main cooling fan utilization percent for that hour. If the supply fan has been scheduled off for a particular hour, no outside air can be delivered to the rooms.

3. The supply fan is controlled in time clock fashion, i.e., if the schedule reads 80% for a particular hour, the fan will operate at full rpm for 80% of the hour and remain off the rest of the hour. Since the supply fan delivers conditioned air to the room, reducing the percent it can operate during a given hour will cause the cooling coil to modulate at a lower temperature (than normal) during the percent of the hour the fan is available. If the fan is not allowed to operate long enough, the room temperature will be allowed to drift, the amount dependent on the magnitude of the unmet space load.

4. Since the fan coil heating and cooling supply air temperatures respond to the room thermostat, supply air reset control is not possible.

Application Notes

● The program assumes that the fan coil system is four-pipe (heating and cooling available all year round). To input a two-pipe fan coil system, the user should indicate which months the heating and cooling functions are to be locked out when creating the main cooling and heating schedules.

● If the fans are to be cycled during unoccupied hours, enter the fan cycling information on the availability manager tab in the system properties.

CV PTHP

The design is peak air and peak cooling capacity.

A separate cooling/heating heat pump is located in each zone. Each unit can draw return air either from a return air plenum above the particular room (return air assignments greater than zero) or recirculate air within the room (return air assignments are zero). The design cooling and heating supply air temperatures are determined from either the Design Phase or user input and cannot be overridden by outside air reset schedules. The fans are constant volume while cooling coils are cycled to meet the load.

System Simulation